scratch test astm|material scratch resistance test : online sales Customers who bought this document also bought: ASTM-E18 Standard Test . Portal de notícias de Cascavel e Região. Mulher mantida em .

{plog:ftitle_list}

Resultado da 18 de set. de 2023 · 1. Introdução. 2. O que é PPSSPP? 3. Como baixar e instalar o PPSSPP. 4. Como baixar jogos PPSSPP. 5. Melhores sites .

This test method is able to characterize the scratch resistance of polymers by measuring many significant material parameters. The scratch-inducing and data acquisition process is .Customers who bought this document also bought: ASTM-E18 Standard Test .

ASTM G171-03 (2017) Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus. Significance and Use. 5.1 This test method is intended to measure .In ASTM D7027-13, the method outlines a strict procedure for assessing the scratch resistance of polymer surfaces. It utilizes an instrumented scratch machine, following the guidelines of the standard.Scope*. 1.1 This test method describes a laboratory procedure using an instrumented scratch machine to produce and quantify surface damage under controlled conditions. This test . Scratch tests are performed on specimens: (1) to evaluate the scratch or mar resistance of a particular material, (2) to rank the relative scratch resistance of different .

In many cases, the scratch test has now become accepted as a versatile tool for assessing the mechanical integrity of a surface, whether bulk or coated, and has found . The new ASTM standard for scratch adhesion testing, ASTM C1624, covers the determination of the adhesion strength and failure modes of hard, thin ceramic coatings on .Scratch Resistance Test Methods. The identification and characterization of surface wear in plastics, is paramount in Product Performance, critical to Quality and invaluable for .

This test method describes a simple and rapid evaluation of a coated material’s resistance (film’s hardness) to scratch effects due to the sliding of pencils of various hardness (6B to >6H), . Scratch Hardness of Materials Using a Diamond Stylus 1 This standard is issued under the Þxed designation G171; the number immediately following the designation indicates . The scratch hardness test, as described herein, is not intended to be used as a means to determine coating adhesion, nor is it intended for use with other than speciÞc . 1 This test method is under the jurisdiction of ASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.30 on Abrasive Wear.

scratch resistance test method

The cure of the coating may also be assessed by this standard. Lastly, this test protocol may be employed after an accelerated aging test in order to characterize the evolution of the hardness of the material over time. For instance, ASTM . Standard Test Method for Evaluation of Scratch Resistance of Polymeric Coatings and Plastics Using an Instrumented Scratch Machine D7027-20 ASTM|D7027-20|en-US Standard Test Method for Evaluation of Scratch Resistance of Polymeric Coatings and Plastics Using an Instrumented Scratch Machine Standard D7027 Standard Test Method for .

5.1 This test is intended to assess the mechanical integrity, failure modes, and practical adhesion strength of a specific hard ceramic coating on a given metal or ceramic substrate. The test method does not measure the fundamental “adhesion strength” of the bond between the coating and the substrate. Rather, the test method gives a quantitative .

The origins of the automated scratch test came as a logical evolution of more basic industrial test methods, such as the knife test (ASTM D6677) [3], the tape peel test (ASTM D3359) [4], the pencil hardness test (ASTM D3363) [5], the pull-off adhesion test (ASTM D4541) [6] and the scrape adhesion test (ASTM D2197) [7]. Such methods are often .

Standard Test Method for Adhesion of Organic Coatings by Scrape Adhesion D2197-16R22 ASTM|D2197-16R22|en-US Standard Test Method for Adhesion of Organic Coatings by Scrape Adhesion Standard D2197 Standard Test Method for Adhesion of Organic Coatings by Scrape Adhesion> new BOS Vol. 06.01 Committee D01 $ 61.00 In stock

1.1 This test method covers laboratory procedures for determining the scratch hardness of the surfaces of solid materials. Within certain limitations, this test method is applicable to metals, ceramics, polymers, and coated surfaces. The scratch hardness test, as described herein, is not intended to be used as a means to determine coating adhesion, nor is . Therefore, minor variation in the scratch’s length from test to test doesn’t significantly affect the total stylus wear and the resulting CAI when variation in scratch length is kept between ±0.5 mm in length (3). . ASTM grants Licensee a limited, revocable, nonexclusive, non-transferable license to access, by means of one or more .The classical ASTM friction test for plastics is a sled test. A sled test's lack of relevancy to scratch testing exemplifies a breakdown of the classical laws of friction. In the photographic film field, a point-contact friction test is more correlative. The ANSI version of this, the Paper Clip Friction Test, is described, and correlations with .

ASTM C1895 is an important test method to determine the Mohs scratch hardness of ceramic materials. The product’s quality and reliability are ensured as a result of these measurements. The manufacturers use this procedure to determine the scratch resistance and durability of ceramic materials enhancing their suitability for various applications.G171 Test Method for Scratch Hardness of Materials Using a Diamond Stylus 1 This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties. Current edition approved Oct. 15, 2013Sept. 1, 2020. Published October 2013October 2020. Scratch 4 MachineProper clamping, clamp clearance, and head-height adjustment.Length: 100mmVelocity: 100mm/s and 25mm/sLoad: 1 to 50 N Constant Rising LoadMa.

ASTM D7187: Standard Test Method for Measuring Mechanistic Aspects of Scratch/Mar Behavior of Paint Coatings by Nanoscratching Abrasion Resistance Agents for Paints, Coatings and Inks View the full range of abrasion resistance agents available today, analyze technical data of each product, get technical assistance or request samples. 5.1 This test is intended to assess the mechanical integrity, failure modes, and practical adhesion strength of a specific hard ceramic coating on a given metal or ceramic substrate. The test method does not measure the fundamental “adhesion strength” of the bond between the coating and the substrate. Rather, the test method gives a quantitative .Professional Automatic Scratch Tester - Precision Scratch Test for Research & Quality Management - Your Number 1 Partner Real values for our customers & clients . Engineered in accordance with international test standards including .

Also described is a new scratch test system which controls the depth of cut rather than the scratch load in order to simulate high-stress abrasion, in which abrasive particles are constrained to a fixed depth of cut. . ASTM International cannot guarantee transit times to international destinations. Customs duty and taxes are the . Standard Test Method for Film Hardness by Pencil Test D3363-22 ASTM|D3363-22|en-US Standard Test Method for Film Hardness by Pencil Test Standard D3363 Standard Test Method for Film Hardness by Pencil Test> new BOS Vol. 06.01 Committee D01 $ 61.00 In stock Significance and Use. A new approach for evaluating the wet-adhesive strength of epoxy-based coatings was carried out based on a recently standardized ASTM/ISO scratch test. A linearly increasing scratch normal load was applied during scratch to induce progressively increased delamination stress at the coating and steel substrate interface. Thus, the applied critical load to cause .

The Paint Adhesion Test Kit, (P.A.T.), contains all of the tools and materials needed, except for the multi-tooth cutter blade, for conducting adhesion tests on paints applied to a flat, uniform surface in accordance with ASTM Test Method D3359, method B and DIN Standard No. 53151. There are two kits available: The Cross Hatch Test Kit (12596) is great for any type of flat . Significance and Use 5.1 Scratch tests are performed on specimens:(1) to evaluate the scratch resistance of a particular material, (2) to rank the relative scratch resistance of different materials, or(3) to determine the scratch coefficient of friction o

ASTM Class 4B. Small flakes of coating appear along the intersections of the lattice pattern, but less than 5 percent is affected. . Please call +1 (888) 287-5227 for further details about our paint scratch test and other coating testing services. Request Form " * * * * * * * * * * Coatings and Paints Testing. Coating Overview; Abrasion . Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus G0171-03 ASTM|G0171-03|en-US Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus Standard G171 Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus> new BOS Vol. 03.02 Committee G02 $ 75.00 In stock

When to Use ASTM D3359 Test Methods A or B. Both of these Test Methods can also be considered variants of the tape-and-peel test, a method for assessing adhesion that has been in use since the 1930s. This test, at the simplest level, involves the examination of the paint film removed after an applied tape is peeled off.

scratch resistance of polymeric

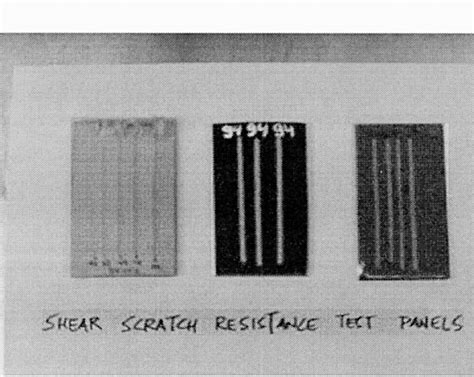

Scratch Resistant Test Methods Test Results Abrasion Resistance Wear Tests Coatings (1) C1,1,1 C1,1,2 C1,2,1 C1,2,2 C2,1,1 C2,1,2 C2,2,1 C2,2,2 Test Units PC 7µm PC 13 µm PMMA 7µm PMMA . ASTM 1044-99,Taber Calibrase CF-10F @ 500g and100 cycles (3) ASTM F 2357-04,Norman Tool Paper (4) Mitsu- Bishi, Hi-Uni Pencils

Scope1.1 This test method covers the determination of the practical adhesion strength and mechanical failure modes of hard (Vickers Hardness HV = 5 GPa or higher), thin (≤30 μm) ceramic coatings on metal and ceramic substrates at ambient temperatures. The . Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings .Mechanical adhesion occurs by the coating adhering to the sanding scratch profile of the surface and by flowing around the fiber of the substrate to mechanically secure the film to the surface. . to assign a value to the adhesive properties of the coating. This procedure follows American standard test method (ASTM) — D2197, D2248, D2454 . The new scratch test method, ASTM D7027-05, provides the guidelines for this investigation [14]. However, in this study, the scratch length was set at 150 mm, instead of the proposed 100 mm, to allow for more precise determination of the onset of critical loads for various scratch damage mechanisms. The test was performed using a linearly .

compression test 2008 ktm 530

compression test 2008 ktm 539

compression test 2008 mini cooper

scratch hardness test method

WEBIsadoraVale (@isadoravale03) no TikTok |315.2K curtidas.61.6K seguidores.Isadora vale 18 anos 👸🏼 VÍD£OS 👇🔥🔥.Assista ao último vídeo de IsadoraVale (@isadoravale03).

scratch test astm|material scratch resistance test